Range of dimension:

– Strip width: minimum 3mm

– Inside diameter: minimum 5mm

– Outside diameter: minimum 8mm, maximum 2000mm

Optional treatments of finished core:

(1)Uncut, non-impregnated.

(2)Uncut, lightly impregnated with epoxy varnish.

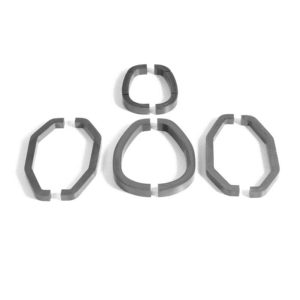

(3)Cut, fully impregnated with epoxy resin.

(4)Multiple-cut, fully impregnated with epoxy resin.

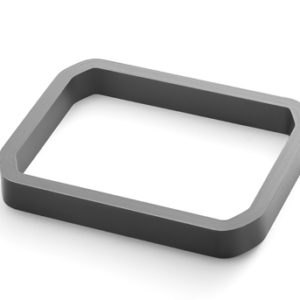

(5)Assembled with plastic cases [PP, maximum working temperature 110ºC, thickness 0.4~0.8mm].

(6)Green epoxy coating [maximum working temperature 180ºC, thickness 0.20~0.50mm].

(7)Black epoxy painting.

Material:

High-quality CRGO steels with the characteristics of low iron-loss and high permeability in thickness of 0.05mm, 0.23mm, 0.27mm, and 0.3mm.

Characteristic:

It is toroidal and wound in the same direction of closed flux path. No magnetic flux leakage. It has the best magnetic performance. It is easy and high-efficiency for coil winding with the toroidal winding machine.

Application:

The toroidal core is widely used in 50Hz and 400Hz transformers, current transformers, reactors, chokes, and other magnetic components of electronic equipment.